Designing flexibility into automated omnichannel distribution

Paul Condron

18 de julio de 2024

Reading Time:

5 minutos

Omnichannel distribution introduces multiple challenges to the general merchandise supply chain. Inventory management becomes more complex, variability in order volumes become more extreme, and the pressure to hold down cost increases. Automation enables retailers to address these challenges with solutions that support more efficient store replenishment and faster, lower cost e-commerce fulfillment. Equally important, the right solution can provide the flexibility to manage resources and inventory across channels.

Keys to omnichannel warehouse automation

Omnichannel warehouses can benefit from a broad range of automation technologies, including pallet and/or carton ASRS, mobile robotics, goods-to-person technologies, sortation systems and packaging equipment.Designing the right solution for a particular facility requires a holistic approach that identifies where automation can deliver the greatest value and considers all viable technologies for each process in the warehouse. Whether automating a single process or the entire warehouse, it’s also beneficial to consider how the chosen solution can accommodate future changes and integrate with scalable automation technologies.

One important decision that deserves attention and focus when considering your automated warehouse design strategy is the automation control system software and execution platform. It’s crucial to avoid software that imposes constraints on operating flexibility or requires extensive customizations, that can add unnecessary costs and delay implementation.

Instead, deploy flexible, agile software with robust functionality. For instance, Swisslog’s SynQ, minimizes the need for customization while offering intelligent synchronization of automation equipment, robotics, people and processes to optimize omnichannel operations in a single, integrated, modular platform. This approach ensures optimal omnichannel operations today and in the future, allowing you to deliver on your promise to customers efficiently.

Managing inventory to support omnichannel distribution

High-volume retailers have the scale to establish parallel distribution networks – one for store replenishment and another for direct-to-consumer fulfillment. While this strategy simplify warehouse design complexity, it can introduce more challenges to manage multiple inventories and minimize operational costs.An alternative approach involves integrating an e-commerce fulfillment into a warehouse designed for retail store replenishment. This simplifies inventory management and enhances operating flexibility.

By combining retail replenishment with e-commerce fulfilment in an omnichannel distribution centre, with the right automation, retailers can achieve several benefits. First, they can reduce order cycle times to better meet customer expectations. Second, late stage inventory flexibility allows retailers to better adapt to demand variability and ensure products are available when customers want them. Finally, this integrated approach creates opportunities to compensate for order spikes, potentially reducing the required warehouse size compared to maintaining separate facilities.

The engine of the flexible omnichannel warehouse

A light-goods shuttle system such as the Swisslog CycloneCarrier, proves ideal for high-volume omnichannel warehouses as it combines high throughput and load handling capabilities with unmatched operating flexibility.CycloneCarrier can handle cartons (both large and small), and totes/bins in the same system. This unified approach allows products destined for both e-commerce and retail store channels to coexist in a common storage system. Omnichannel retailers benefit from more dynamic options for optimized storage, enhanced control and improved visibility across warehouse operations, inventory, and material flow.

In an omni-channel environment, some shuttle workstations can be configured to support cluster picking for e-commerce fulfillment while others are optimized for picking to totes for store replenishment or delivering sequenced cartons to a palletizing station. A proven software platform such as Swisslog’s SynQ can orchestrate inventory management, automation, goods-to-person/manual picking, downstream sortation, labeling and packing. As a result, the light goods shuttle system can achieve the ultimate blend of speed, efficiency and flexibility for omnichannel distribution operations.

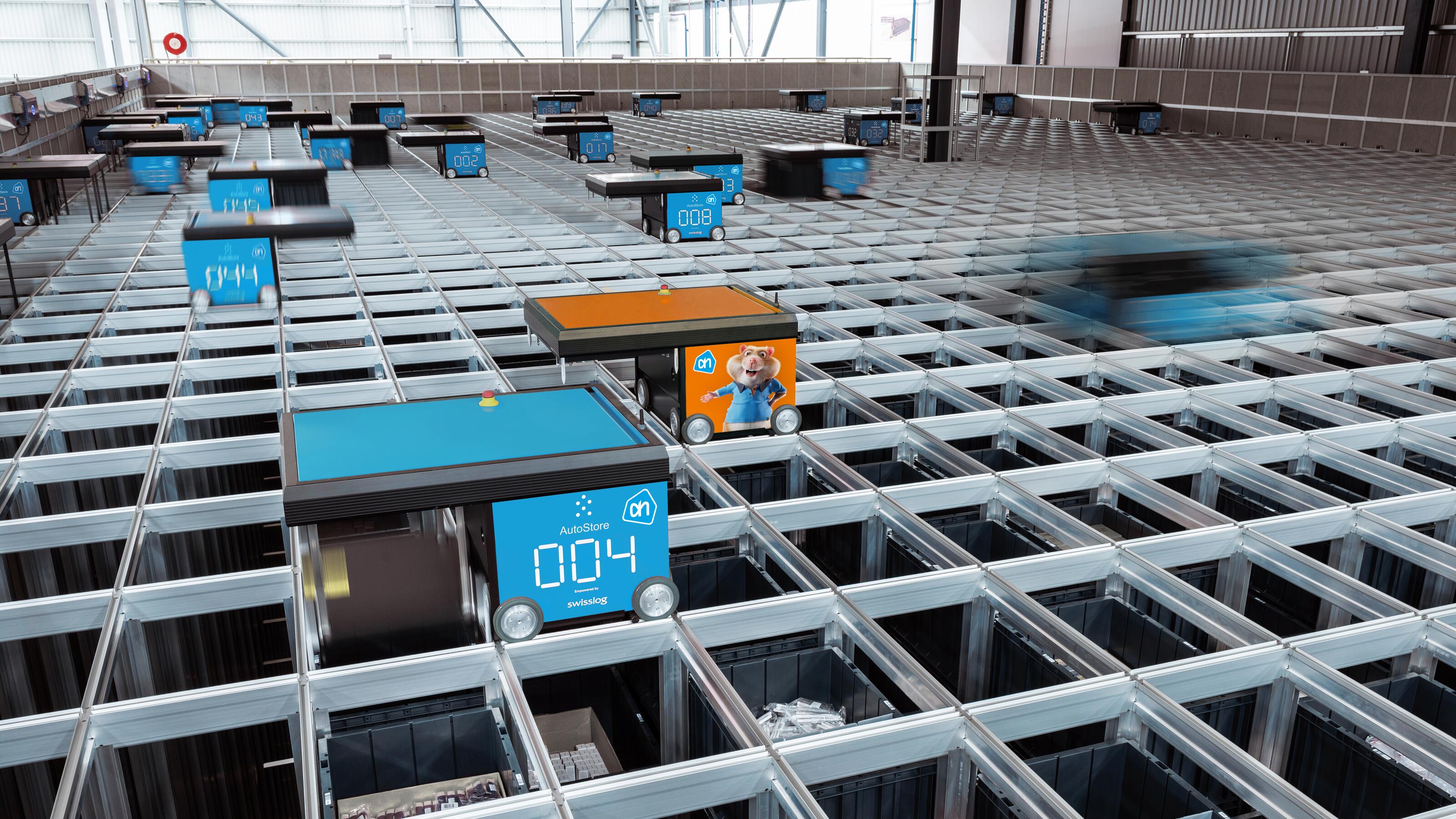

For omnichannel warehouses prioritizing e-commerce fulfillment efficiency, an AutoStore goods-to-person solution from Swisslog has many benefits. As a leading integrator of the ultra-dense AutoStore system, Swisslog boasts over 400 projects worldwide with control software including unique features that unlock productivity and throughput levels.

Automating the omnichannel warehouse

Strategically designing and deploying warehouse automation and software, in collaboration with a partner like Swisslog, empowers retailers to achieve several critical goals:

- Reduced order cycle times: Automation streamlines processes, ensuring faster order fulfillment and improved customer satisfaction.

- Agility and efficiency: Automation allows retailers to adapt swiftly to demand peaks and accommodate growth without compromising efficiency.

- Inventory control: Retailers can gain better visibility and management across channels.

- Optimized overall omnichannel operations: Swisslog’s holistic and consultative approach to omnichannel solution design maximizes flexibility.

To learn more about our solutions for general merchandise, visit our website or contact us.