Pepsi, USA: Increased storage capacity by 61.5%

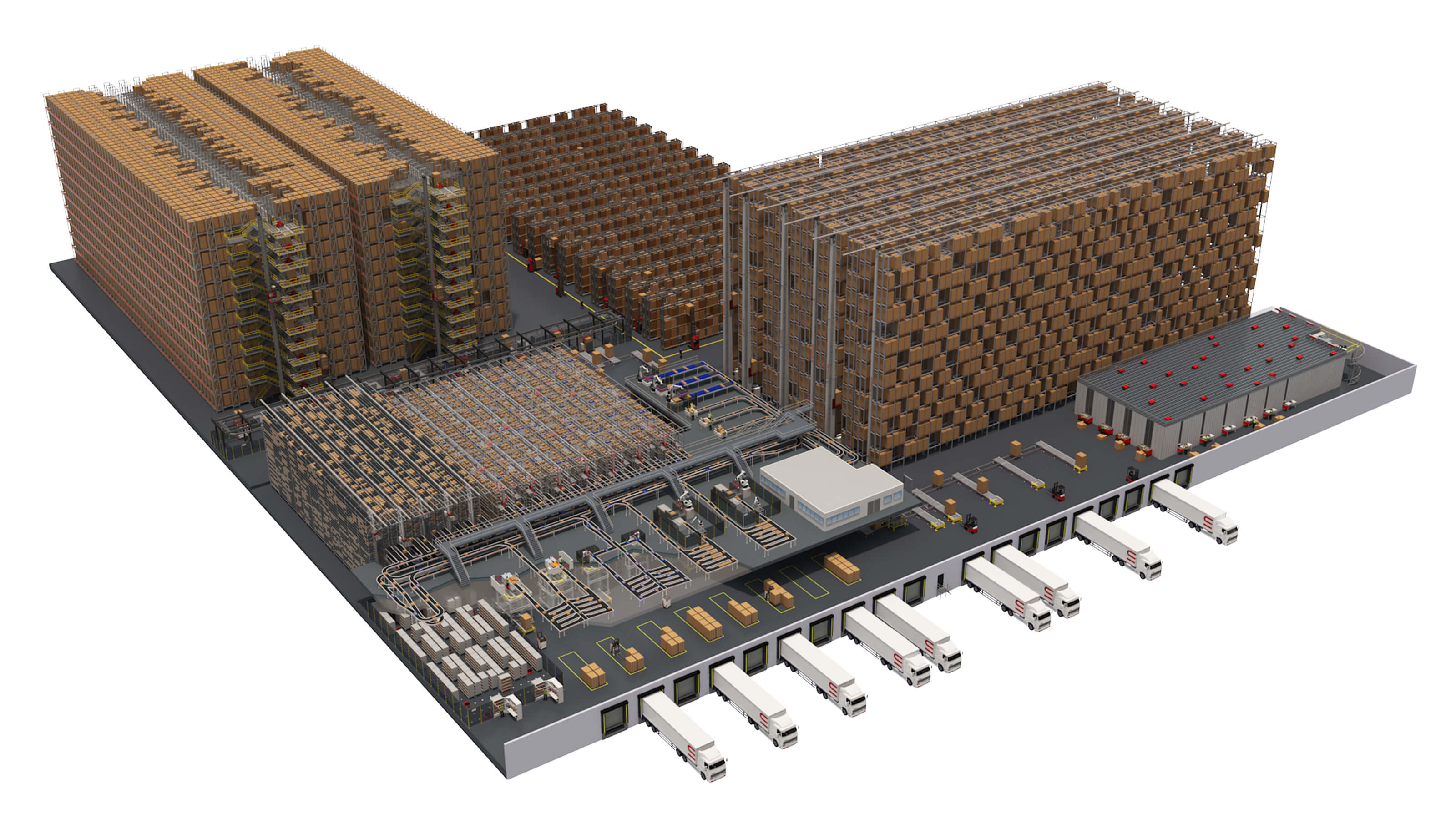

Pepsi Bottling Ventures (PBV) in Garner, NC, USA has installed the revolutionary Swisslog PowerStore™pallet shuttle warehouse automation technology. The nation‘s largest privately-held manufacturer, seller, and distributor of Pepsi-Cola beverages, chose PowerStore technology to increase storage capacity by over 60 percent in its existing flat-ceiling building.

Storage capacity increased by 61.5 percent

Pallets in the 54,000 square foot warehouse were previously stored on the floor up to four high. PowerStore ™ enabled Pepsi Bottling Ventures to:

- Increase storage capacity by 61.5 percent

- Seamless distribution of 7,800 pallets

- Double layer induction/deduction for ease of use by lift drivers increase throughput and employee productivity

- Seamlessly integrate software with existing ERP system

Constant fulfillment with just enough automation

Swisslog designed and implemented the Batesville distribution center using advanced warehouse execution software (WES) to help workers quickly and accurately pick and pack orders.

- Can handle a wide variety of SKU volume and velocity

- Highly flexible and scalable solution

- Includes split-case pick modules, cart picking from bin rack locations, cold-storage picking and pack-out stations.

An overall traditional expansion would have been less desirable because it builds in permanent, long- term inefficiencies through greater fork-lift travel time and facility heating and cooling costs.