What are the challenges of using pallets in AS/RS warehouses?

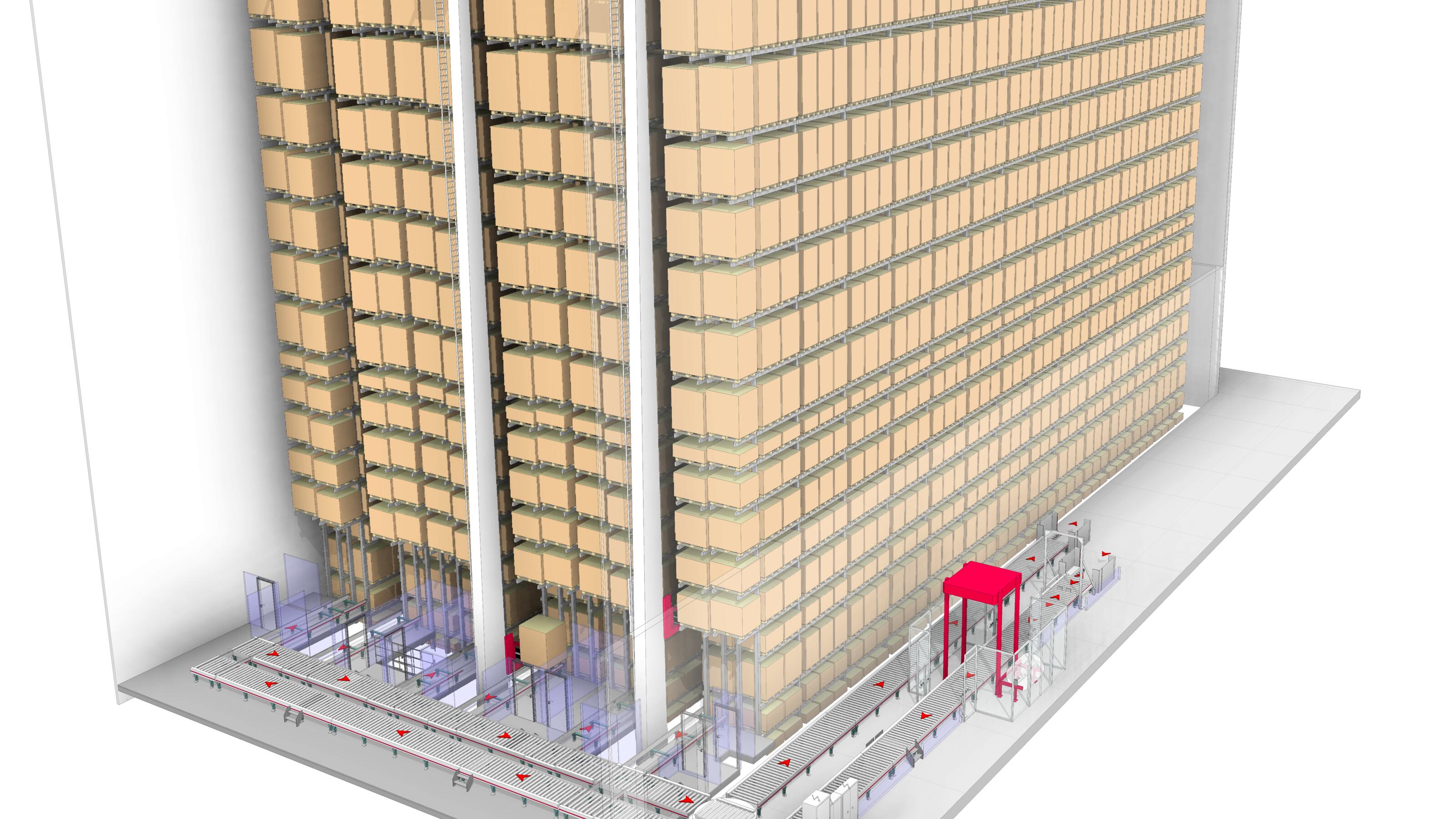

Automated Storage and Retrieval Systems (AS/RS) are increasingly being adopted to enhance warehouse efficiency and accuracy. The integration of pallets within these systems can present significant challenges in sectors from pharmaceuticals to food.

- Adapting to changes in pallet sizes

- Adjustable pallet stackers and handling systems

- Handling systems for mixed pallets

- Operation process

- Platform stackers vs stand-in stackers

- Platform stackers

- Stand-in stackers

- The key differences between stand-in and platform stackers

- Pallet compatibility and consistency

- Industry-specific issues: temperature and material challenges

- Mixed pallets and load positioning challenge

- Pallet durability and workplace safety

- Enhancing workplace safety and hygiene

1 Adapting to Changes in Pallet Sizes

One of the primary challenges in AS/RS warehouses is adapting to changes in pallet sizes. This is crucial for industries that handle diverse products or operate in dynamic markets, such as the food industry, where product lines frequently change. To address this, automated pallet warehouses can implement flexible automation systems, including adjustable pallet stackers and handling systems capable of accommodating various pallet sizes.

1.1 Adjustable pallet stackers and handling systems

Adjustable pallet stackers and handling systems for mixed pallets in automated storage and retrieval systems (AS/RS) offer flexible solutions for efficiently storing and retrieving diverse pallet loads.

- Telescopic Forks can extend and retract to accommodate different pallet depths, allowing for single-deep or double-deep storage configurations.

- Variable Fork Spacing can adjust their width to handle pallets of different sizes, increasing flexibility.

- Sensors and load cells are used to detect pallet dimensions and weight, ensuring proper handling and storage.

1.2 Handling Systems for Mixed Pallets

To efficiently manage mixed pallets in an AS/RS, several technologies and approaches are employed:

- Intelligent Load Profiling: Advanced sensors and cameras scan incoming pallets to determine their dimensions, weight, and load distribution. This data is used to optimize storage locations and handling procedures.

- Dynamic Slotting: The warehouse management system (WMS) uses real-time data to assign optimal storage locations based on pallet characteristics and retrieval frequency. This maximizes space utilization and improves retrieval efficiency.

- Multi-depth Storage: Systems can incorporate single-deep, double-deep, or even multi-deep storage options to optimize space usage for different pallet types.

- Automated Load Stabilization: For unstable or irregularly shaped loads, automated wrapping or strapping stations may be integrated into the system.

- Flexible Extraction Systems: Stacker cranes may be equipped with various load handling devices, such as telescopic forks, Pallet Shuttles, or on-board conveyors, to accommodate different pallet types and storage depths.

1.3 Operation Process

The operational process within an Automated Storage and Retrieval System (AS/RS) begins with the induction of mixed pallets into the system. Upon entry, each pallet undergoes scanning to ensure accurate identification and profiling. This initial step is crucial for establishing the characteristics of the pallet, such as its dimensions, weight, and content, which are then used to optimize its subsequent handling.

Following identification, the Warehouse Management System (WMS) assigns the pallet to an optimal storage location within the facility. This assignment is based on a combination of the pallet's characteristics and predefined system parameters, such as storage density and retrieval priority, ensuring that the pallet is stored in the most efficient manner possible.

The pallet is then transported to its designated storage location by stacker cranes or other automated vehicles. These vehicles are specifically designed to navigate the warehouse environment and place the pallet in its assigned slot using precise handling mechanisms tailored to the pallet's specific requirements.

When retrieval is necessary, the system locates the pallet and employs the appropriate handling approach, which may involve adjustments based on the previously stored data about the pallet. This ensures that the retrieval process is both efficient and accurate, minimizing the risk of errors or damage.

Finally, the retrieved pallets are delivered to picking stations or outbound processing areas as required. This outbound processing step ensures that the pallets are ready for further distribution or use, seamlessly integrating with the overall logistics operations.

1.4 Platform stackers vs stand-in stackers

Both are types of powered pallet handling equipment, but they do have some key differences:

1.4.1 Platform Stackers

Platform stackers are versatile machines that feature a fold-down platform at the rear where the operator stands. This design offers the flexibility to operate in both pedestrian and ride-on modes. When operating in pedestrian mode, the platform and side bars can be folded up, allowing for ease of movement in tight spaces. In ride-on mode, these stackers typically offer faster travel speeds compared to pedestrian stackers, making them well-suited for longer and more frequent shuttle runs. While platform stackers are more maneuverable than stand-in models, they are slightly less compact than pedestrian stackers. However, their design and speed contribute to higher productivity, particularly for medium-distance transport tasks.

1.4.2 Stand-in Stackers

Stand-in stackers are designed with the operator fully enclosed within the structure of the truck, providing a high level of protection during operation. This enclosed design not only enhances safety but also contributes to the overall efficiency of the machine, making it particularly well-suited for high-intensity operations and tasks that involve covering longer distances. Stand-in stackers often feature a more compact footprint, which allows them to navigate narrower aisle widths and achieve higher storage density within the warehouse. In terms of performance, they are generally faster and more powerful than platform stackers, offering superior speed and power for demanding tasks. Additionally, these stackers are designed with operator comfort in mind, making them ideal for longer shifts and more frequent use, thereby improving overall productivity and operator satisfaction.

1.4.3 The Key Differences Between Stand-in and Platform Stackers

The primary distinction between stand-in and platform stackers lies in their design. Stand-in stackers fully enclose the operator, providing a more protected environment, whereas platform stackers feature an open design with optional side bars for added safety. This difference in design has significant implications for space efficiency and operational flexibility.

Stand-in stackers typically allow for narrower aisle widths, maximizing storage density within a warehouse. Their compact footprint and enclosed operator position make them ideal for environments where space is at a premium. In contrast, platform stackers offer greater operational flexibility, enabling the operator to switch between pedestrian and ride-on modes depending on the situation. This makes platform stackers particularly useful in environments where the ability to maneuver in tight spaces is essential.

When it comes to productivity over long distances, stand-in stackers generally excel. They are better suited for intensive operations and longer travel distances, offering higher speeds and improved operator comfort. The enclosed design also enhances safety, providing greater protection for the operator, which allows for more confident and faster operation, particularly in narrow aisles.

When choosing between stand-in and platform stackers, it is important to consider factors such as typical travel distances, frequency of use, aisle widths, and the need for operational flexibility within your specific warehouse environment.

2 Pallet Compatibility and Consistency

Ensuring pallet compatibility and consistency is another major concern for AS/RS warehouses. Traditional wood pallets often lack the precision and uniformity required for automated systems, leading to issues such as system inaccuracies, equipment malfunctions, and potential downtime. This problem is particularly acute in the food industry, where even slight variations in pallet dimensions can cause significant disruptions, especially in environments where high throughput is essential.

To mitigate these issues, many warehouses are transitioning to engineered plastic pallets, which offer greater reliability and consistency. In industries like pharmaceuticals, where the stakes are higher due to stringent regulatory requirements, the use of consistent, high-quality pallets is non-negotiable.

3 Industry-Specific Issues: Temperature and Material Challenges

Temperature-controlled environments, such as cold storage facilities commonly used in the food and pharmaceutical industries, present unique challenges for pallets. Wood pallets, for instance, are prone to absorbing moisture and becoming brittle in freezing temperatures, leading to breakage or warping. This not only compromises the structural integrity of the pallets but also poses risks to the stored products.

In contrast, plastic pallets offer superior performance in such environments due to their resistance to moisture and temperature fluctuations. However, the choice of pallet material remains critical. While plastic pallets provide consistency and durability, they may come at a higher initial cost, which can be a consideration for industries operating on tight margins.

4 Mixed Pallets and Load Positioning Challenges

Mixed pallets, where different types of products or pallet types are used within the same system, can be particularly challenging for AS/RS warehouses. Precise load positioning is essential in automated systems, and any variation in pallet dimensions or quality can lead to misalignments and operational disruptions. This is especially problematic in deep-lane systems, where pallet quality is critical to system functionality.

In industries like pharmaceuticals, where different batches of products may require different handling procedures, the use of mixed pallets can complicate warehouse operations. To mitigate these challenges, some warehouses employ engineered plastic pallets designed specifically for AS/RS environments, ensuring consistent performance and reducing the risk of system failures.

5 Pallet Durability and Workplace Safety

The durability of pallets is a key consideration in AS/RS warehouses, particularly in industries with rigorous handling requirements. Wood pallets, while traditional, suffer from moisture sensitivity, pest vulnerability, and structural weaknesses, making them less durable and reliable. These issues are particularly concerning in the food industry, where pallet durability directly impacts product safety and quality.

Plastic pallets, on the other hand, offer significant advantages in terms of moisture resistance, chemical resistance, and impact resistance, making them a more durable option. Their longevity, often extending beyond 10 years, also makes them a cost-effective choice over time. For industries like pharmaceuticals, where maintaining a sterile and safe environment is critical, the durability and hygiene benefits of plastic pallets are particularly valuable.

6 Enhancing Workplace Safety and Hygiene

Plastic pallets also contribute to improved workplace safety and hygiene, which are critical considerations in industries like food and pharmaceuticals. Unlike wood pallets, plastic pallets eliminate hazards such as nails, splinters, and broken boards, reducing the risk of workplace injuries. Their lighter weight and smoother surfaces further minimize the risk of strains, sprains, and other injuries, making them safer for manual handling.

In terms of hygiene, plastic pallets offer superior benefits due to their non-porous surfaces, resistance to bacteria and mold, and ease of cleaning and sanitization. These features are particularly important in pharmaceutical and food processing environments, where maintaining high hygiene standards is crucial. The resistance of plastic pallets to moisture and chemical absorption further reduces the risk of contamination, ensuring that the products remain safe and compliant with industry regulations.

The integration of pallets within AS/RS warehouses presents numerous challenges that vary across different industries. While wood pallets have traditionally been used, the shift towards engineered plastic pallets is becoming increasingly prevalent due to their durability, consistency, and hygiene benefits. In industries like pharmaceuticals and food, where maintaining strict safety and quality standards is critical, the advantages of plastic pallets make them an ideal choice. As AS/RS technologies continue to evolve, the selection and management of pallets will remain a crucial factor in optimizing warehouse operations and ensuring the safe, efficient handling of goods.