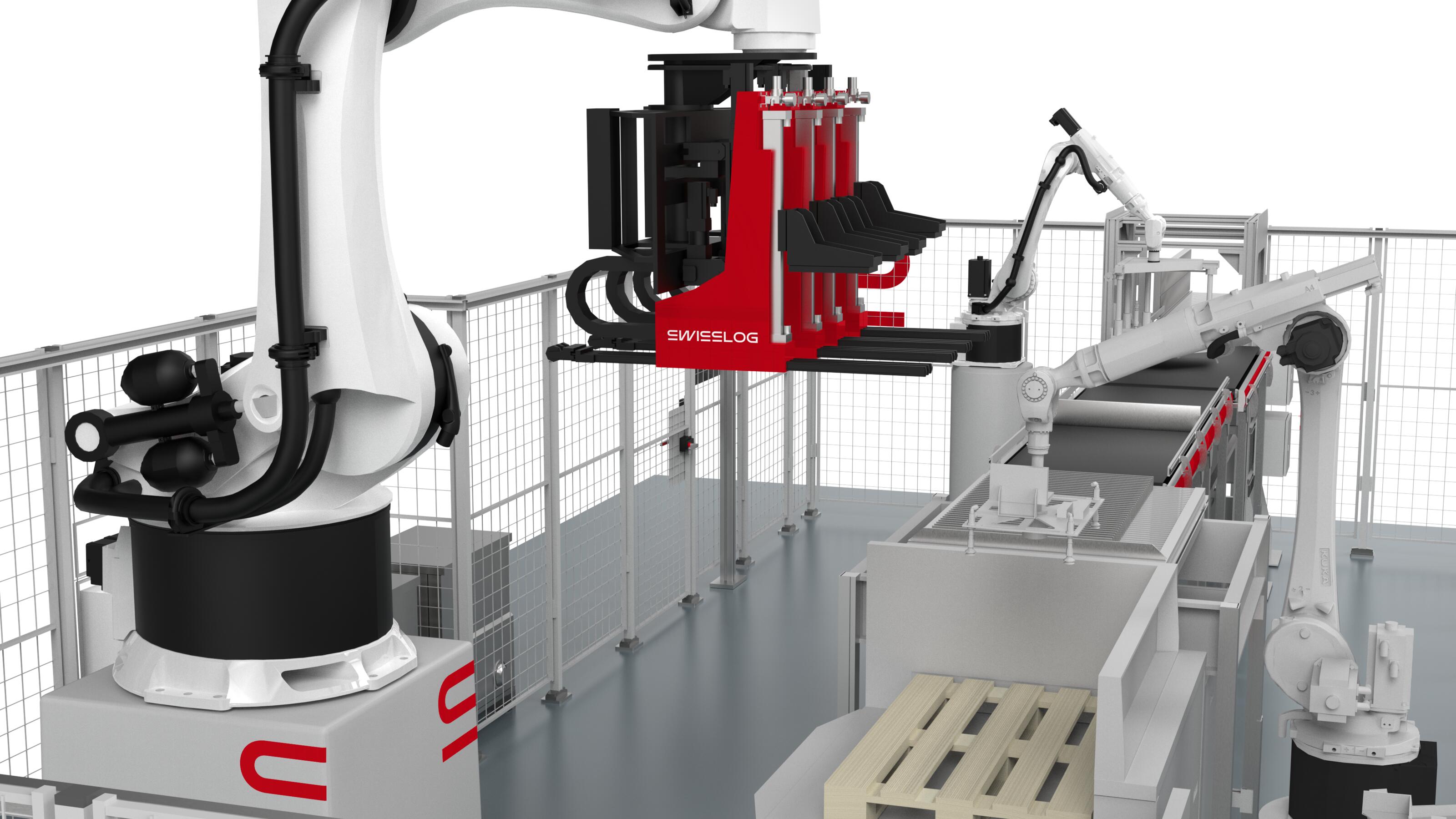

Robots improve your warehouse efficiency

Customer requirements for goods diversity, individualization, freshness, and delivery speed are constantly growing. It’s no longer same day delivery, it’s next hour delivery.

Picking and palletizing make up to 60% of your warehouse operational costs, and are the most time consuming processes in your warehouse. Workers to do it are becoming harder to find nowadays too. Only a very high degree of automation and self-learning smart-data systems can meet today’s diverse and growing demands.