Yusen Logistics, Singapore: Order fulfilment rate increased by 200%

Yusen Logistics Singapore launched a new robotic, automated warehouse featuring AutoStore by Swisslog, an automated storage and order picking system. AutoStore is a technological leap in warehousing technology that aligns with Yusen’s vision of achieving a smart logistics operation. The AutoStore solution that implemented by Swisslog is designed to specifically operate in a high-mix, high-volume operation. Multiple customer’s products are stored in the bins and robots running on the grid deliver goods to goods-to-person workstations.

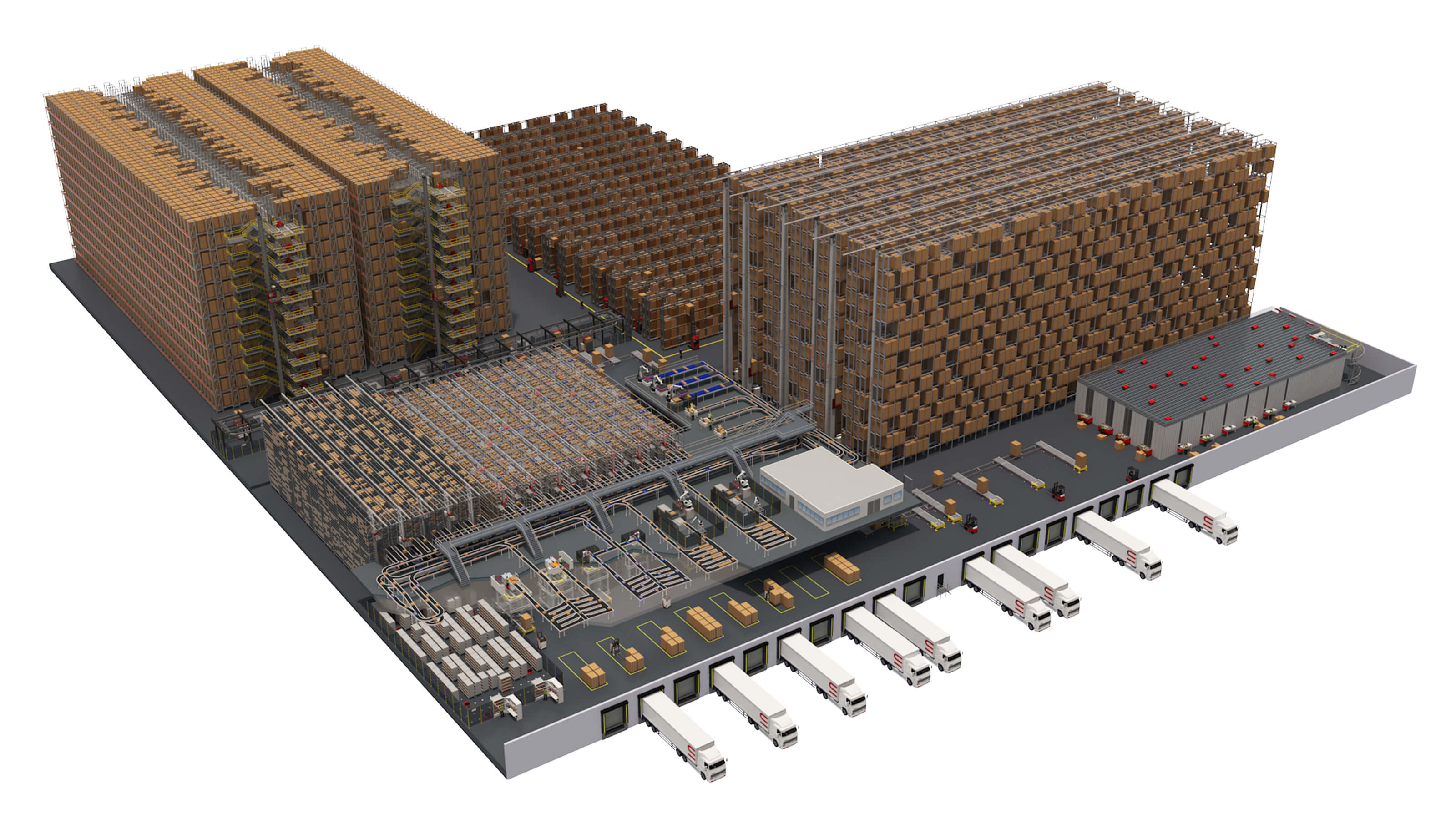

Advanced Automated Warehousing System

The Swisslog AutoStore solution, designed to specifically operate in a high-mix, high-volume operation, in a massive grid measuring LWH 60m x 20m x 5.4m features:

-

40,600 AutoStore bins

-

22 robots

-

11 goods-to-person workstations

-

Swisslog Warehouse Management System

First mover advantage to provide same-day delivery

AutoStore by Swisslog not only helps Yusen Logistics to improve the operation but also gives the company first mover advantage to provide same-day delivery, which is a significant competitive advantage.

- Optimizing storage volume from 2,000 cubic metres to 3,500 cubic metres, in the same floor space

- Order fulfilment rate increased by 200%

- Increased throughput up to 18 times for high volume and high mix operations

- Future ready innovative and smart technology

This AutoStore system not only helps Yusen improve the operation but also gives the company first mover advantage to provide same-day delivery, which is a significant competitive advantage.