Alnatura, Germany: Sustainable, Industry 4.0 logistics

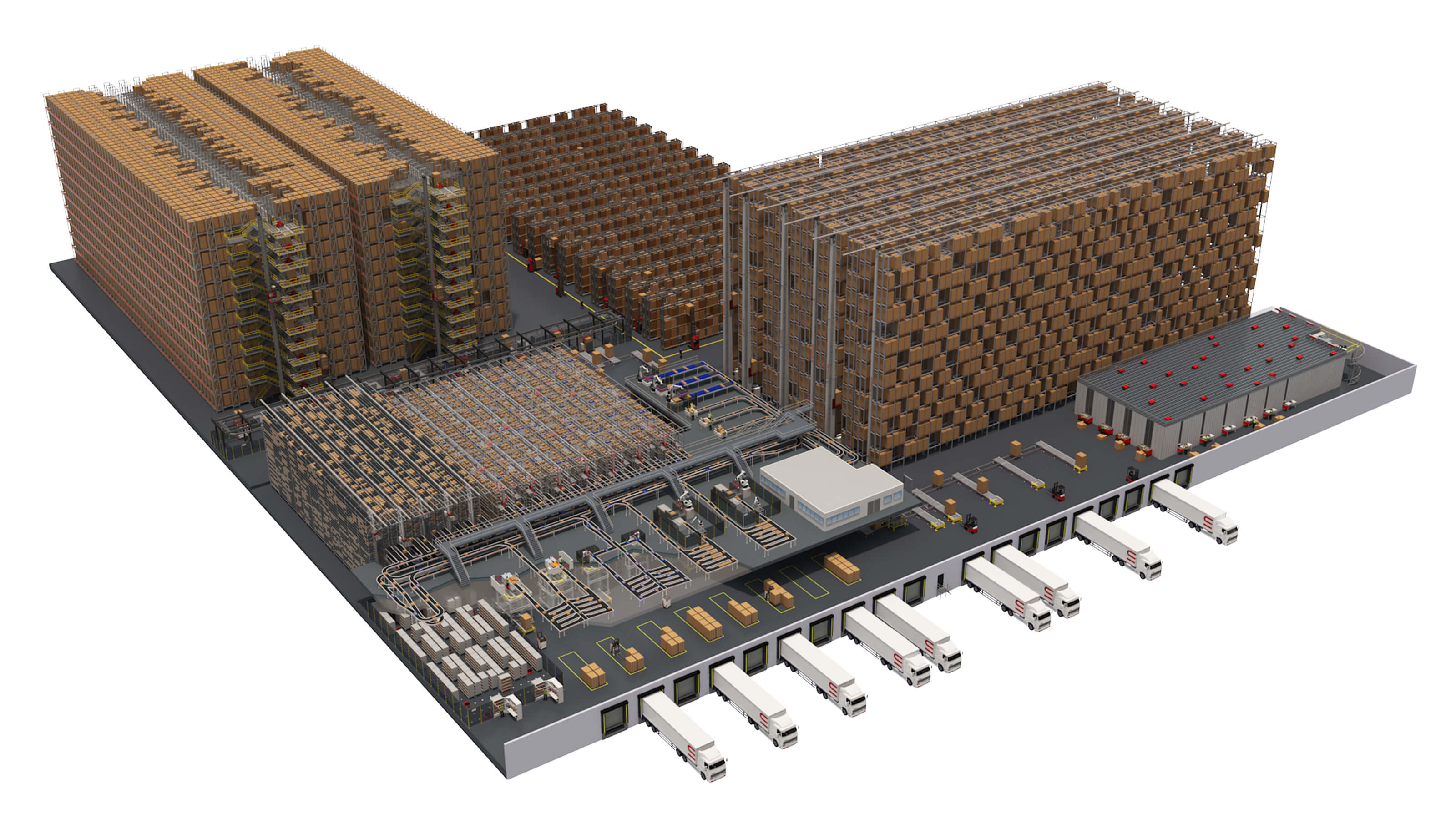

The sustainable distribution center with high bay warehouse at Alnatura in Lorsch, Germany rises to a height of 17.5 meters and is made entirely of wood. The new logistics center will cut CO2 emissions. Thanks to good insulation and natural cooling, neither heating nor artificial refrigeration is required. Innovative Industry 4.0 logistics automation ensures the efficient and highly dynamic flow of goods from receiving to storage, and from picking to shipping to store delivery.

Dynamic, reliable small load storage with CycloneCarrier

Using Swisslog’s innovative and highly dynamic CycloneCarrier warehouse shuttle system allows Alnatura to supply its expanding store network with low-volume personal care items from one central location. The environmentally sound solution shortens transport routes and lets Alnatura manage a larger SKU range.

Ready for Industry 4.0 & future challenges

The CycloneCarrier shuttles are automatically controlled by Swisslog's management software system SynQ. The intelligent and predictive system is modular and can be implemented with other "Intelligence Services". One of these is 3D visualization, which allows users at Alnatura to see the whole warehouse operation in real-time and to detect errors much earlier. Thanks to SynQ, Alnatura is now ready for future challenges.

Full spectrum of automated materials handling

We are happy to finally have a highly dynamic shuttle solution. CycloneCarrier is the heart and growth engine of our logistics service.