ACPaQ: Fast and reliable automated mixed case palletizer

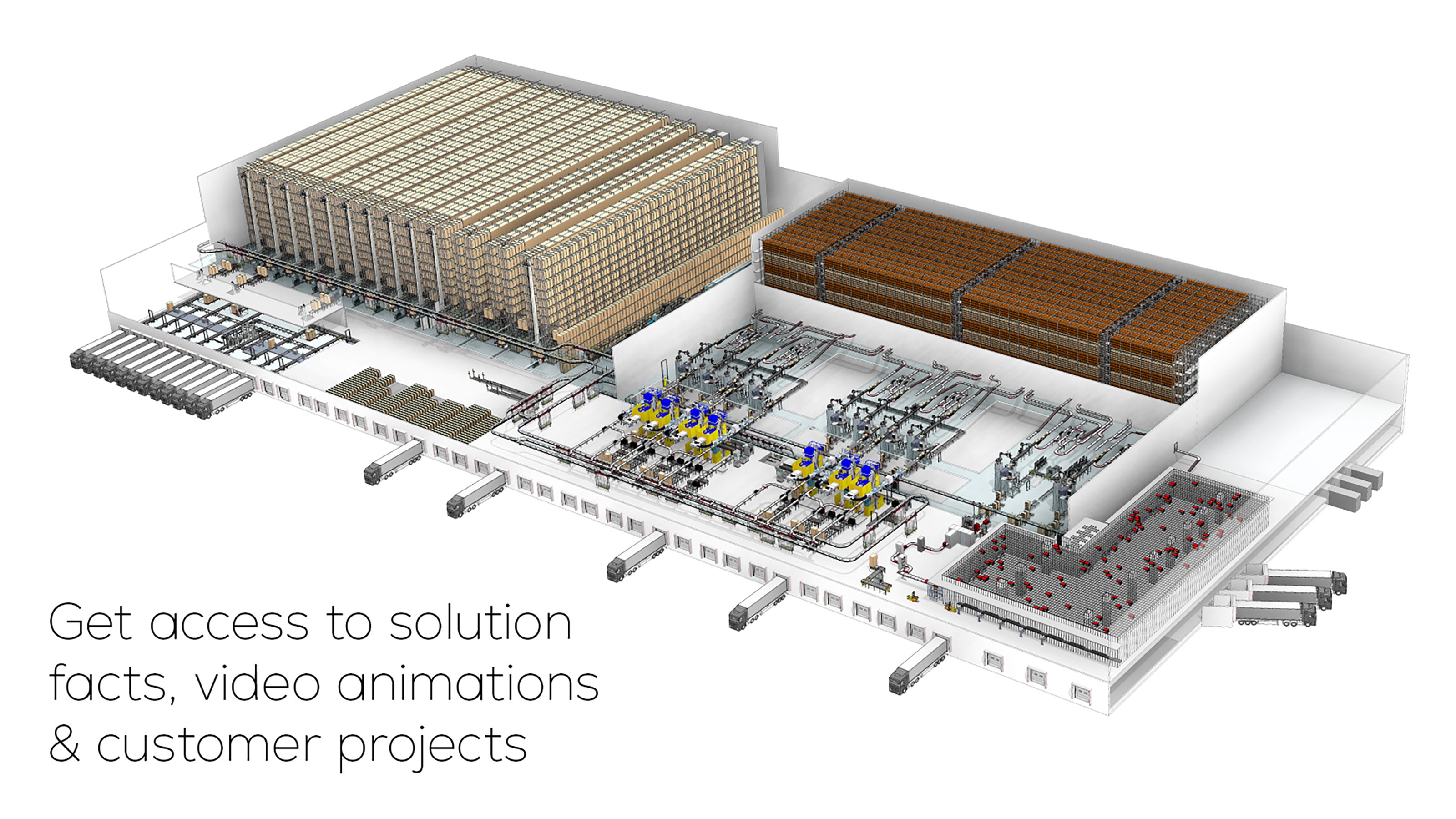

Does your distribution center need a palletizing solution that is fast, reliable and able to grow as you grow? ACPaQ is a robotic and data-driven solution for store-friendly mixed case palletizing.

A data-driven mixed case palletizing solution

ACPaQ combines proven Swisslog technology, such as the light goods shuttle system CycloneCarrier and conveyor systems, with high performance KUKA de-palletizing and palletizing robots to create a fully automated system for order picking of mixed case pallets.

Each pallet is always built stable, correct and store-friendly, based on individual store planograms, reducing your in-store shelf refilling costs. It is also flexible enough to start with a semi-automated solution and add modules as your business grows to eventually move to a fully automated solution.