ACPaQ: Videos & factsheet

Discover more details about the advanced Swisslog mixed-case palletizing solution.

3 main processes: Case Palletizer ACPaQ

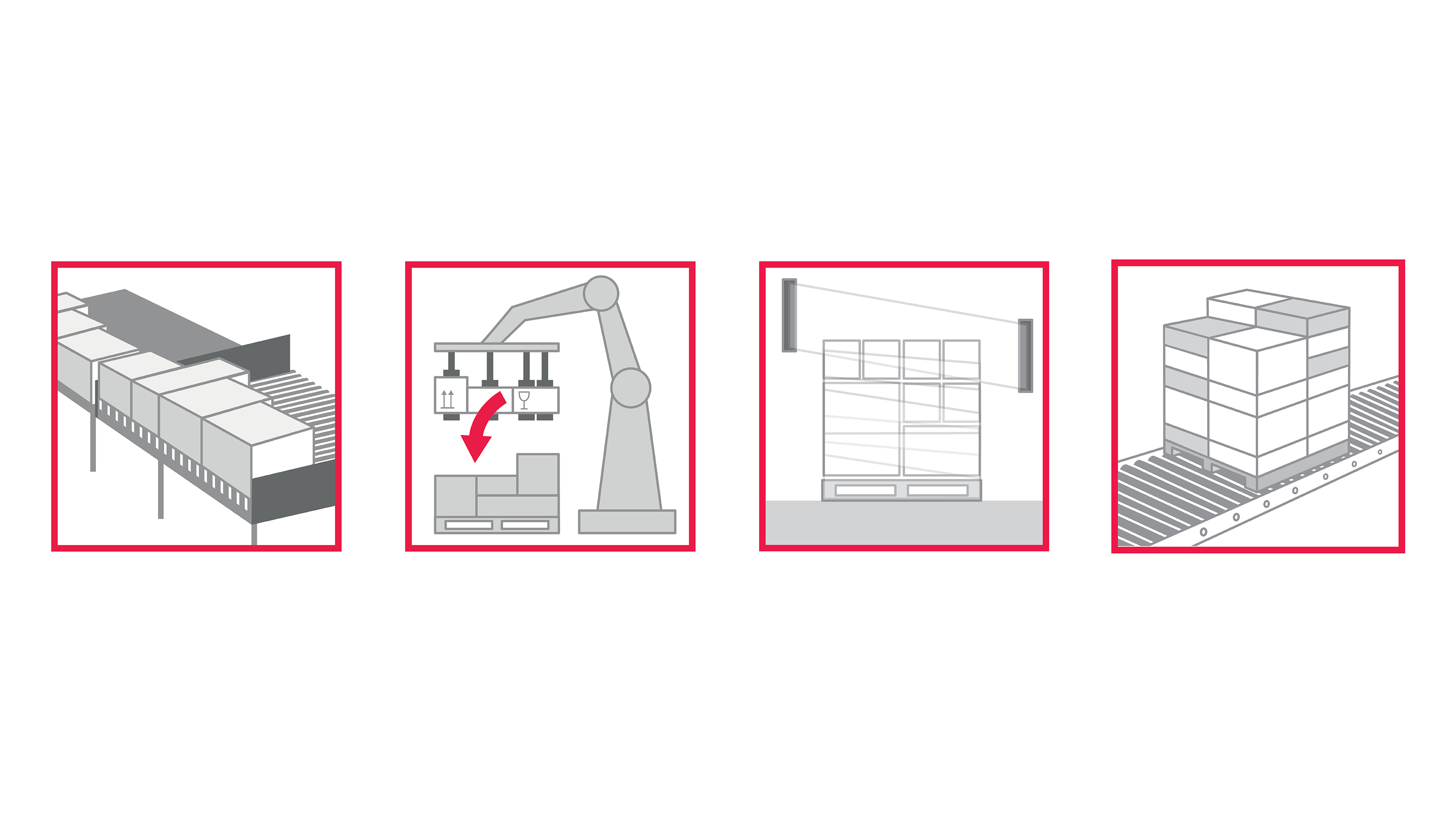

a) Goods arrive in homogenous pallets

b) They are automatically

i. stored in the pallet storage, or

ii. depalletized layer by layer by a depalletizing robot for replenishment

c) The depalletizing robot positions the pallet layers on a conveyor belt

d) The layers are descrambled

e) The single cases are loaded automatically into trays

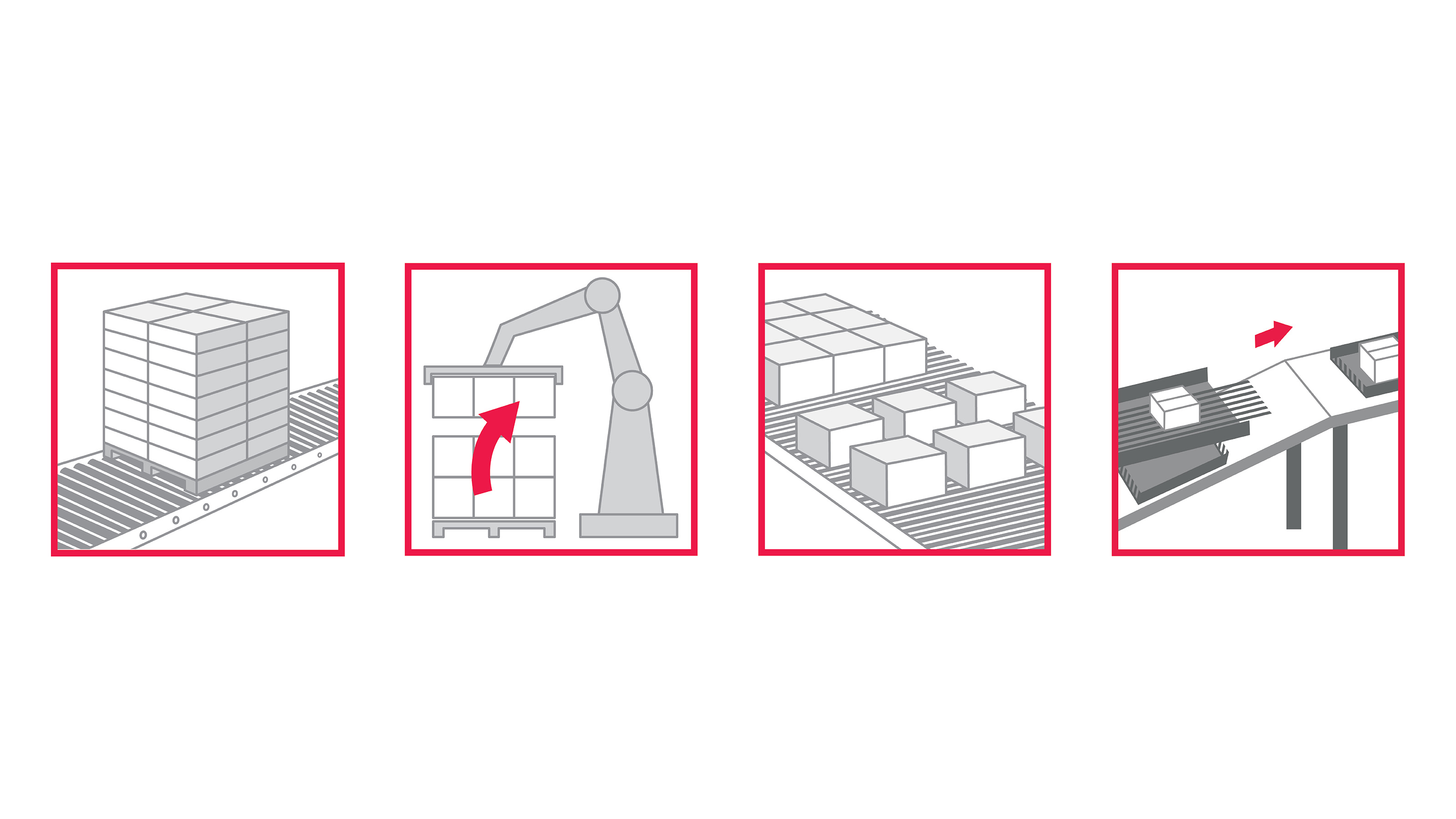

a) The cases are stored in a multi-level storage served by CycloneCarrier for case buffering

b) After order assignment, the cases are released from the case buffer and are put into the right sequence by the sequencer

c) The single cases are unloaded from the trays

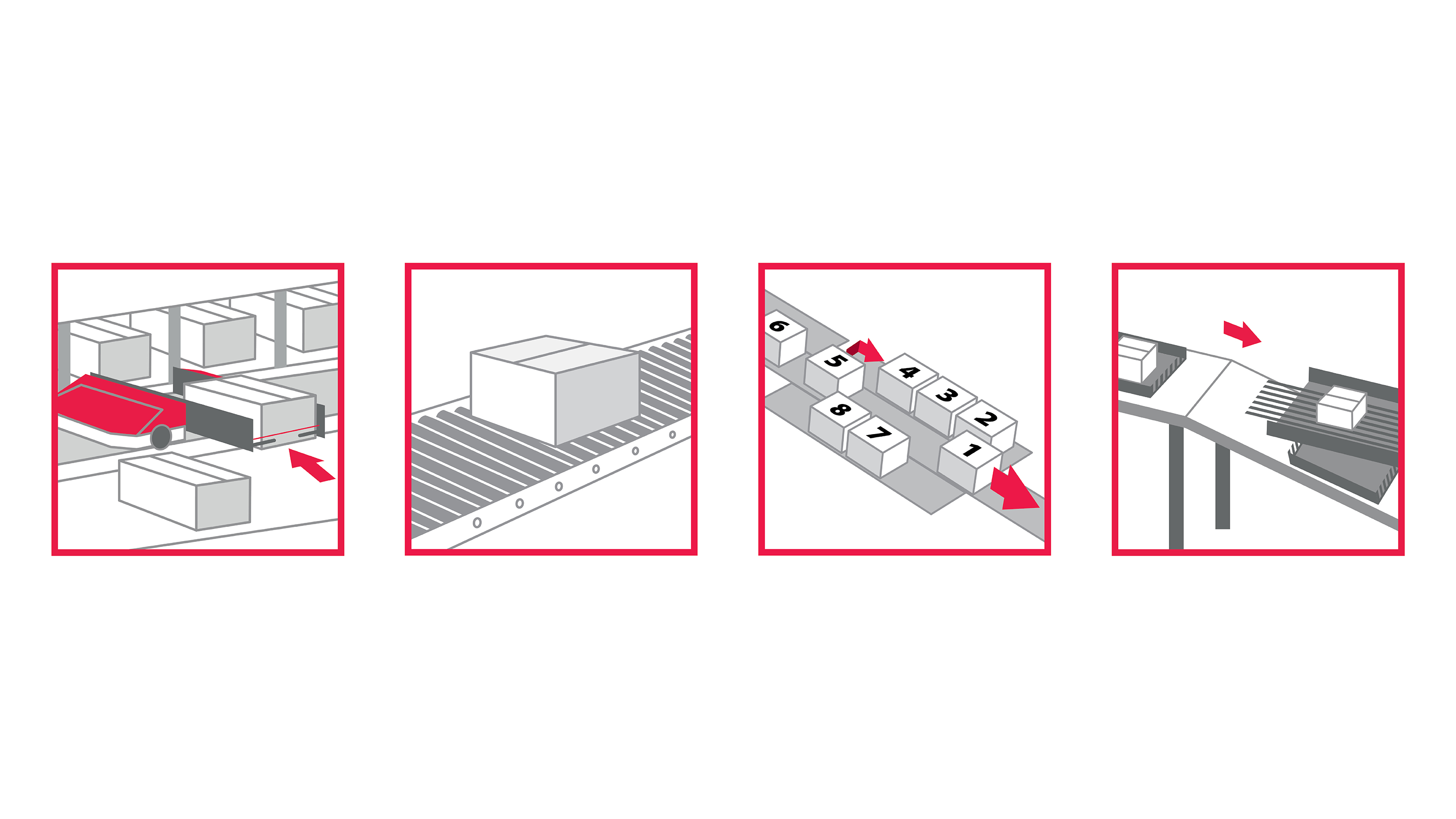

a) The conveyor between the tray unloader and the palletizer forms a row of cases according to the palletizing pattern, which is released when the pick-up conveyor is empty

b) RowPaQ palletizes up to four cases in a single movement allowing a row-by-row principle

c) The order pallets are load-secured by a wrapping machine in the robot station

d) The secured pallet is labelled and transported to the dispatching area