Vera Bradley, USA: Automated distribution center designed for future growth

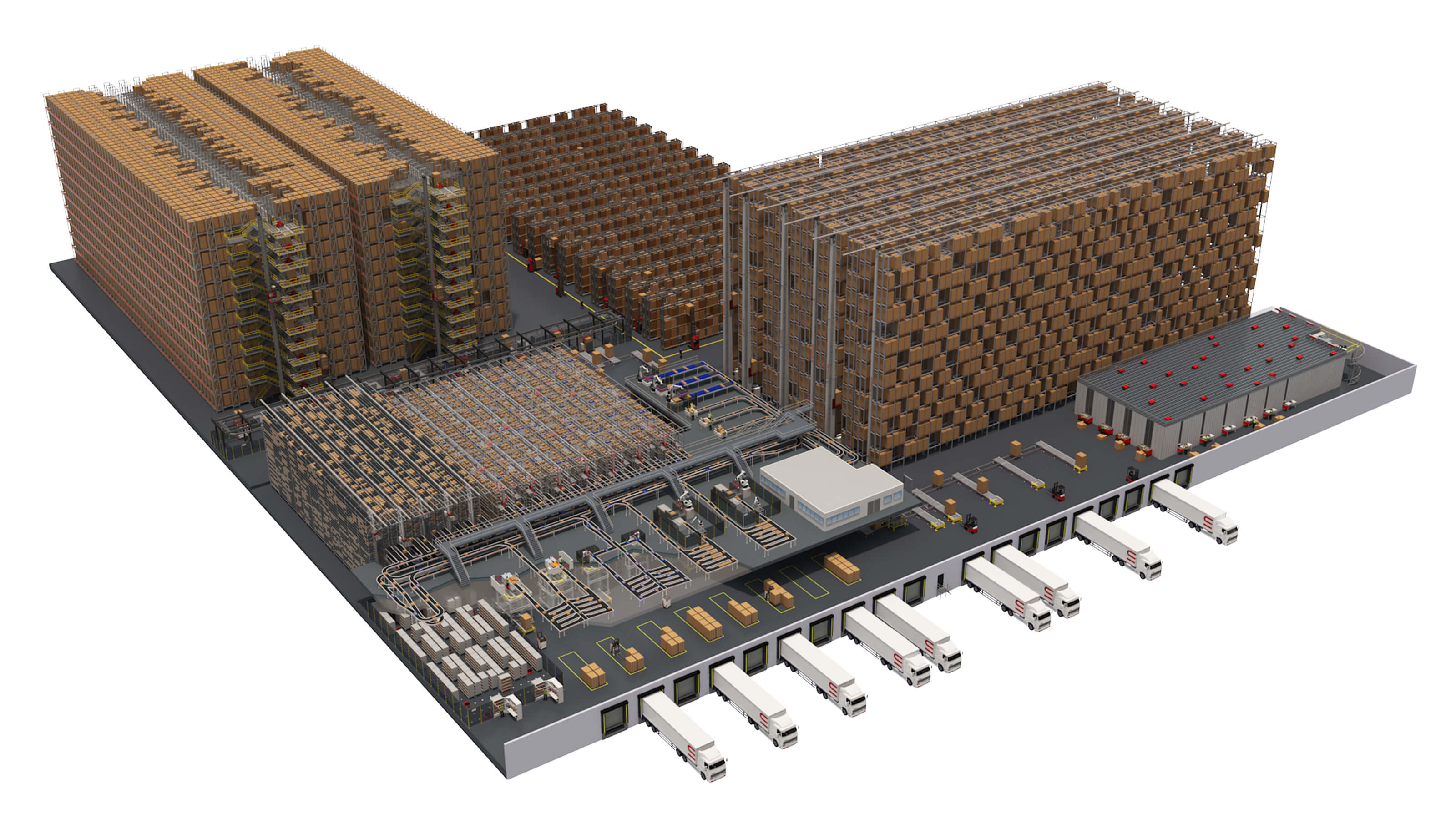

Founded in 1982, Vera Bradley is one of the fastest-growing brands in the retail industry, selling fashionable and colorful handbags, accessories, luggage and paper and gift items through more than 3,000 retail partners, ranging from small boutiques to big box retailers. FORTE (now Swisslog) planned, designed and implemented a highly automated 200,000 square foot distribution center around the brand’s anticipated rapid growth with a flexible, scalable approach to expansion.

Multichannel facility for planned expansion

Vera Bradley also sells its products through more than 160 of its own retail store locations and discount outlet stores, as well as online at verabradley.com, resulting in needing new ways to service a true multichannel distribution model under one roof. With explosive growth, both inbound receiving, shipping dock and finished goods storage capacity became limited resulting in 50% of Vera Bradley’s inventory being stored offsite. This led to a decline in picking efficiency, less space for value-added processes and a degrading of service levels.

The solution was to implement a facility expansion that included warehouse execution software for intelligent conveyance, system performance forecasting, warehouse simulations and much more.

Productivity and picking accuracy improvements

Over the next five years, Vera Bradley went above and beyond expectations by growing its e-commerce operations, doubling its revenue, opening 80 more retail stores and going global with distribution to Japan.

Other benefits included:

- State-of-the-art picking and packing processes

- Productivity increase of 25 percent

- Picking accuracy improvement to 99.5 percent

- System designed for continued growth

The project scope and timeframe were aggressive and ambitious. You met our high expectations from the outset and continue to be a partner in successfully meeting our supply chain objectives. With your assistance, we have transformed our supply chain from a constraint to an enabler of our growth strategy.