Swisslog automates new Home Shop Center of Albert Heijn in Barendrecht

27. marraskuuta 2023

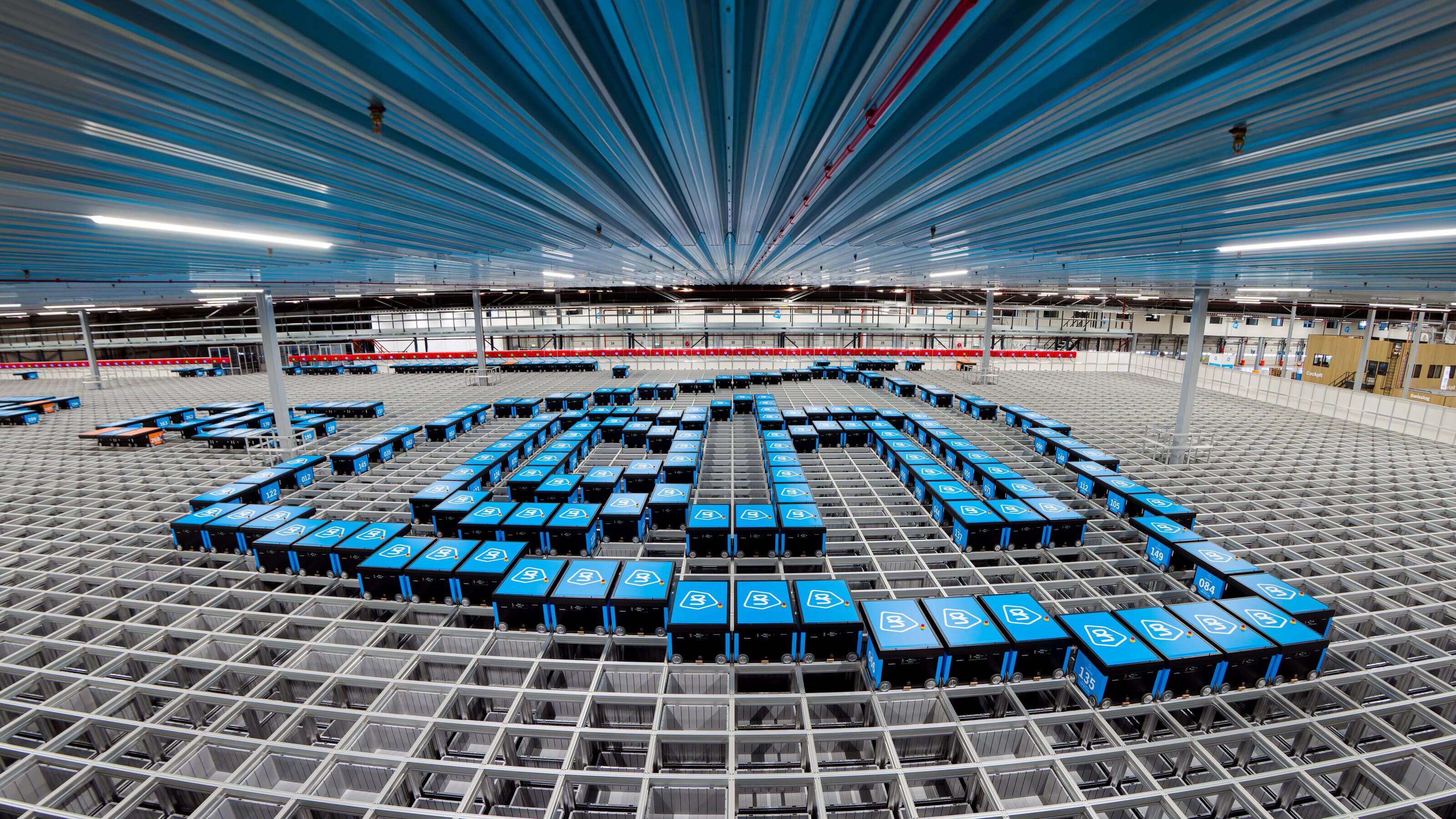

Albert Heijn's new automated Home Shop Center (HSC) is launching soon. This innovative project, created in collaboration with Swisslog, has involved automation of their warehouse using an Autostore system. In the HSC, bins of peanut butter and tubes of toothpaste automatically roll along an ingenious, automated network of rails to end up in the familiar blue shopping crates that are delivered to customers' homes. The new HSC is in Barendrecht and will handle 45,000 orders every week.

Marit van Egmond, CEO Albert Heijn: "As the largest e-commerce player in supermarket country, Albert Heijn is committed to innovation, growth and sustainability. In doing so, we continuously look for the latest technologies to work smarter and more efficiently. I am proud of the new step we are taking in our HSC in Barendrecht. With this, we are tapping into yet another opportunity to continue to grow with e-commerce, while taking into account the tightness of the labor market."

Human and technology

For automated filling of grocery crates, Albert Heijn is deploying an automated system with robots and bins to quickly collect perishables. This innovative project includes the establishment of an automated fulfilment center, aimed at direct home delivery. The HSC project involves several processes, including booking, storage, sorting and loading using QuickMove conveyors, the integration of SynQ software, and the implementation of AutoStore, a robot-controlled storage and order picking system.

Soon some 300 robots with a total of 45,000 totes will move at lightning speed through the new HSC to collect groceries ordered for customers. This will make work lighter for employees. In the new HSC, people and technology work hand in hand. Employees complete the orders, including adding fresh products. For the automation project, Albert Heijn entered into a partnership with Swisslog. Even after implementation, Swisslog remains involved by providing support and optimization through technical support thanks to the deployment of a dedicated Swisslog team on site to detect any malfunctions, analyze data and improve processes as necessary.

Innovative and sustainable

As well as being innovative, the new HSC is also sustainable. Like all Albert Heijn's other HSCs and DCs, the completely gas-free building will receive BREEAM certification because of various sustainable energy solutions such as 5,400 solar panels, an energy-efficient cold store, energy-efficient LED lighting and a heat pump for the climate system in the offices. And with 63 charging points, the HSC is ready for the transition to electric driving.

The HSC in Barendrecht will soon start handling customer orders in this new way. Meanwhile, the construction of the next automated HSC has already started. That opening is scheduled for mid-2024 in Zwolle.