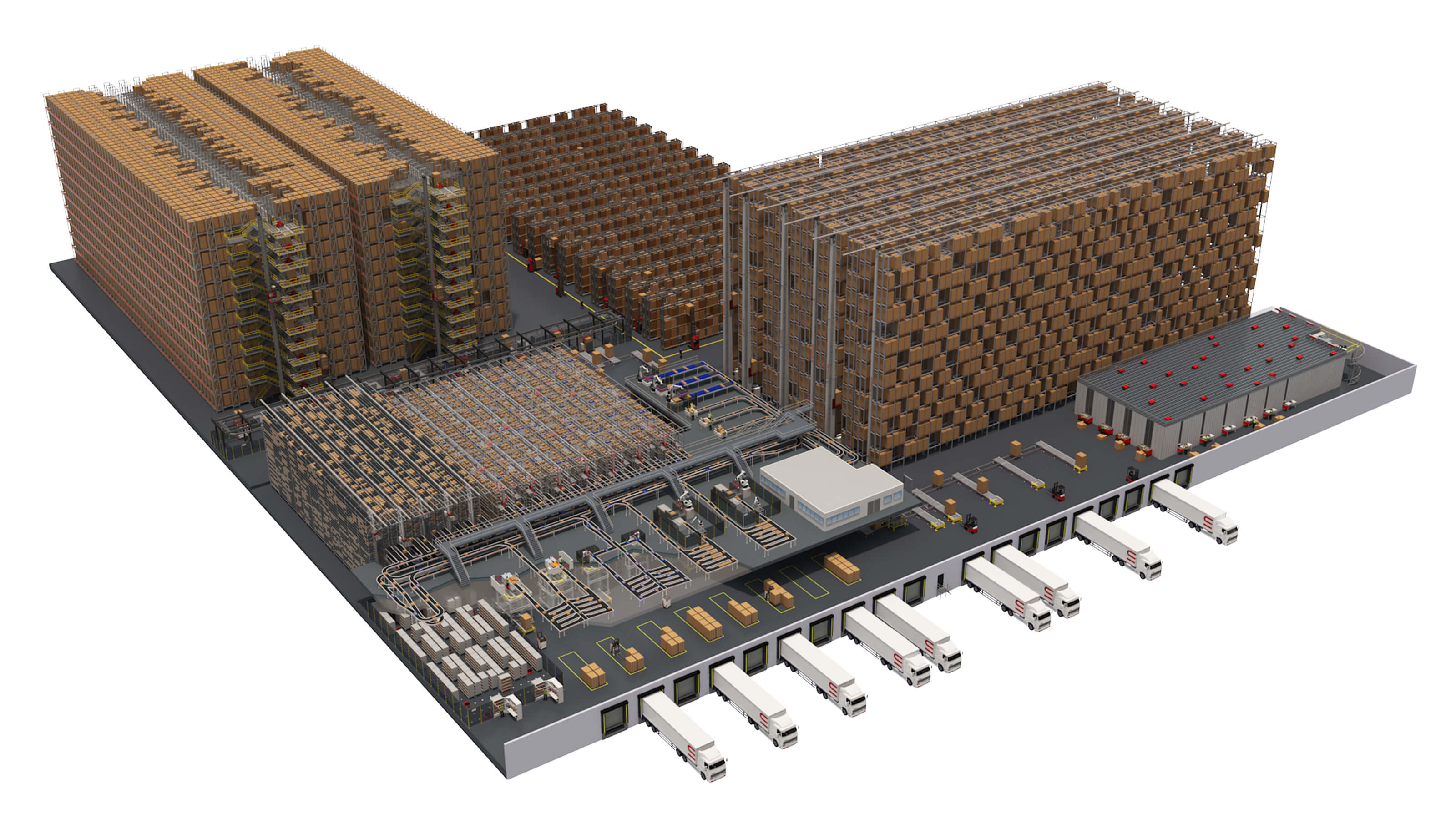

Almarai, Saudi Arabia: Refrigerated high volume palletizing and storing

The Saudi Arabian group Almarai is one of the largest vertically integrated dairy companies in the world. To serve the growing domestic and international markets, Almarai invested in automated picking, stacking and storing solutions from Swisslog and KUKA for their palletized fresh and refrigerated foods.

Full automation in complex climatic conditions

Challenged by the climatic environment with an extremely high temperature range (from +50 ° C outside to 3° C - 5° C in refrigerated environment), several warehouses have been installed for palletized finished goods and a fully automated picking and goods distribution center.

Technologies include:

- Swisslog Vectura pallet stacker cranes for the high bay warehouses

- Swisslog ProMove conveyors for pallets Automatic Reefer Loading System (ARLS)

- Swisslog Monorail, Electric suspension system; >40 in Consolidation Facility only

- Automatic picking modules supplied by KUKA

- SAP EWM, (Extended Warehouse Management System) to control the material flows and data intelligently and efficiently.

Store-ready pallets with robot layer picking

The cases are stacked in layers on pallets, using the monorail technology designed by Swisslog to transport the pallets in the buildings to the picking stations. The picking stations are able to build store-ready, mixed SKU pallets, according to the customer’s order. The robot picks up an entire layer and places it in a position in the buffer area specified by the SAP EWM software.

Augmented Reality Customer Service

To ensure that the new logistics center runs smoothly and is ready for Industry 4.0, Almarai uses the Swisslog System Operation service concept (24/7) and the latest augmented reality service features.

By optimizing the logistics processes, we can create a clear competitive advantage for Almarai.